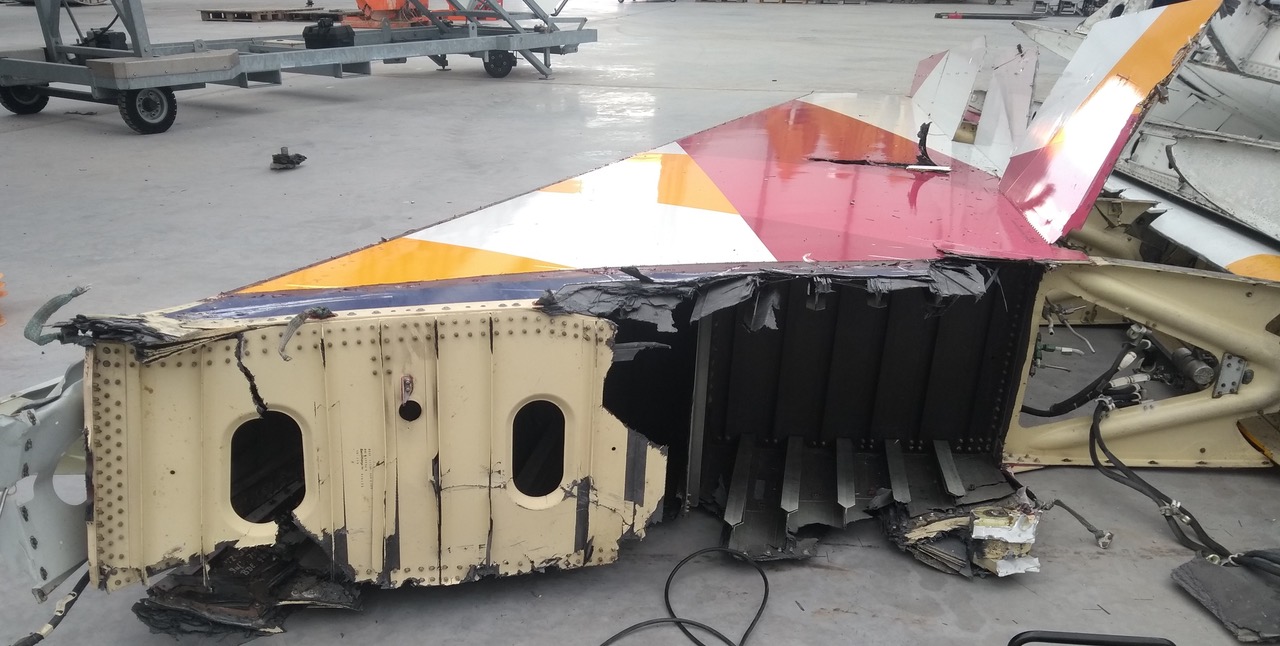

Aerocircular N.V with registered office at International Airport Ostend-Bruges, Belgium and ELG Carbon Fibre, Ltd. with registered office at Coseley, UK join forces in establishing a closed-loop recycling scheme for End-of-Life aircraft CFRP waste streams, having signed a Memorandum of Understanding between both companies.

Carbon fibre is a high strength, high stiffness material that when combined with an epoxy resin matrix creates a composite with exceptional mechanical properties. Next to aircraft, carbon fibre is being used in wind turbines, automobiles, sporting goods, and many other applications. A closed-loop recycling scheme implies a shift from carbon fibre as disposing waste towards a material that can be used for recovery and reproduction.

“Today, composite EoL fractions are typically shredded and burned or landfilled”, says Aerocircular CEO Koen Staut. “By joining forces with ELG Carbon Fibre as an established international player in the field of carbon recycling, the ambition is to establish a closed-loop recycling process of our EoL aircraft carbon composite material stream, maximizing value via a joint approach in further developing the recycling process and new product development using this reclaimed carbon fibre”. Stein Janssens, Director R&D adds: “The cooperation with ELG will allow a robust, economically viable recycling flow with impact on an industrial scale. Doing so, every tonne of carbon fibre from the aircraft we process to a new material saves 20 tonnes of GWP CO2eq. at only 1/10th of the energy required compared to producing virgin carbon fibre”.

“Recycling post-industrial waste from aircraft manufacturing activities has demonstrated the economic, technical and environmental benefits that this new class of materials can deliver”, says Frazer Barnes, Managing Director of ELGCF. “By working with Aerocircular and expanding our activities into post-consumer waste from end-of-life aircraft, we are preparing to address the challenge that will be faced when carbon fibre intensive structures reach the end of their lives. This is an important step in ensuring that the carbon fibre composites industry plays its part in meeting the environmental challenges we all face”.

27th July 2020